Meat Packaging Plant Wastewater Case Study

A California grocery meat packaging plant generates 100,000 gallons per day of wastewater containing animal fats and grease. The wastewater collects in an aerated holding pond (one-day retention time) prior to discharge into the city sewer system. A microbe-based product from Grace Dearborn was used in the past but had little success as BOD and TSS readings were increasing to an average of 300 mg/l and 1,500 mg/l, respectively. BioWorld Waste & Odor Treatment was added twice a week to digest solids and lower BOD measurements. Within one week, the BOD and TSS readings were reduced to an average of 20 mg/l and 30 mg/l, respectively. On-going treatment has reduced the fats and grease in the system and maintained the low BOD and TSS readings.

Lagoon Before and After Treatment

The wastewater passed through a treatment system and into an aerated holding pond. Another product was used in an attempt to help digest the grease and reduce BOD/TSS readings.

BioWorld Wastewater Treatment products were applied. The grease and fats were safely degraded, BOD/TSS readings were brought into compliance and odors were eliminated. The facility saved over $50,000 in one year using the BioWorld Technology.

Proven Industrial Wastewater Treatment Technology

Part of the clarifier has grease and fats using the old methods.

The clarifier has very small amounts of solids after using the BioWorld Products.

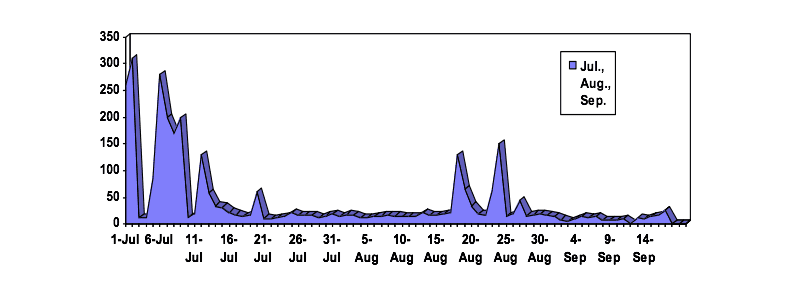

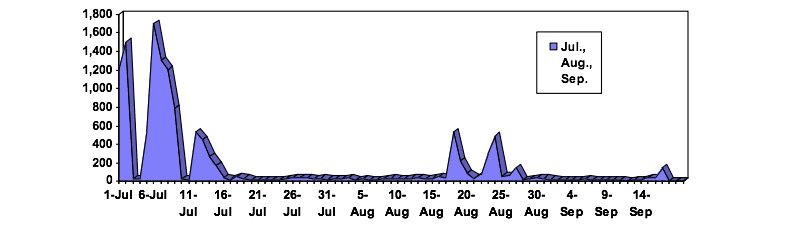

Daily Totals for the Months

of July, August, and September

BOD mg/l